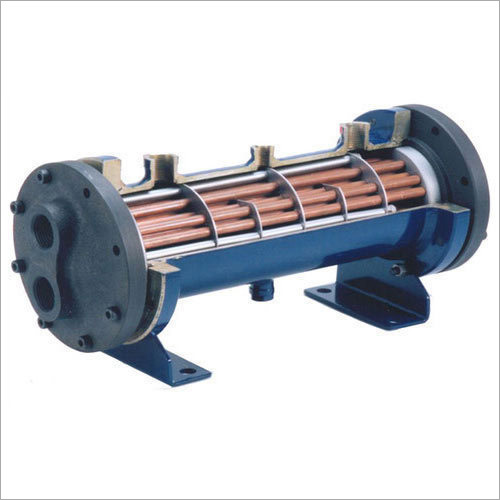

Special Purpose Machine Oil Cooler

Product Details:

- Number of Pipe 3

- Condition New

- Structure tube Heat Exchanger

- Voltage 220-440 Volt (v)

- Click to View more

Special Purpose Machine Oil Cooler Price And Quantity

- 1 Unit

Special Purpose Machine Oil Cooler Product Specifications

- New

- 3

- tube Heat Exchanger

- 220-440 Volt (v)

Special Purpose Machine Oil Cooler Trade Information

- Cash Advance (CA)

- 1 Week

- As per requirement

- All India

Product Description

A Special Purpose Machine (SPM) Oil Cooler is a specialised cooling system made to control and keep the lubricating oil used in a variety of industrial machinery and equipment at the proper temperatures. To guarantee the efficient operation and longevity of the devices, it offers a number of features and advantages.

The usual characteristics and advantages of an SPM Oil Cooler are listed below:

Features:

1. Compact Design: SPM Oil Coolers frequently have a small footprint, making it simple to put them inside machinery or in confined spaces.

2. Heat Exchanger: To transmit heat away from the oil, these coolers use a heat exchanger. A network of tubes or plates make up the heat exchanger, which maximises surface area for effective cooling.

3. SPM Oil Coolers are made to have a high cooling efficiency, ensuring that the lubricating oil is kept within the ideal temperature range. This avoids overheating, which can result in device problems, oil degradation, and viscosity loss.

4. Cooling Medium: To dissipate the heat produced by the lubricating oil, these coolers employ various cooling mediums, such as air or water. Depending on the machine's unique needs and the environment it runs in, the cooling medium is chosen.

5. SPM for Temperature Control Temperature control devices like thermostats or electronic controllers are frequently seen in oil coolers. By varying the cooling intensity in accordance with the demands of the machine, these aid in maintaining a constant oil temperature.

6. Strong Construction: SPM Oil Coolers are often built from sturdy materials like aluminium, stainless steel, or copper alloys to survive the harsh industrial environments. This ensures durability and resilience to mechanical stress and corrosion.

Benefits:

1. Improved Machine Performance: SPM Oil Coolers encourage greater machine performance by maintaining the lubricating oil at the ideal temperature. Consistent oil temperatures support viscosity maintenance, friction reduction, and effective lubrication, which boosts machinery production and decreases downtime.

2. Extended Equipment Lifespan: Oil degradation can be accelerated by overheating, which causes machine parts to prematurely wear out. By minimising severe heat-related damage and lowering the need for regular maintenance, SPM Oil Coolers contribute to extending the lifespan of equipment.

3. Energy Efficient: Proper temperature control minimises energy loss brought on by excessive cooling or heating. By keeping the oil temperature within the specified working range, SPM Oil Coolers optimise energy consumption, saving money and having a smaller negative impact on the environment.

4. Preserving Oil Quality: Excessive heat can lead to oil oxidation and degradation, which decreases the efficacy of lubrication. SPM Oil Coolers ensure the durability and continual maintenance of the lubricating oil's quality, retaining its lubricating characteristics.

5. Increased System Reliability: SPM Oil Coolers help to increase system reliability by preventing overheating and maintaining constant oil temperatures. This lowers the possibility of unanticipated failures and expensive repairs, increasing industrial machinery's operational effectiveness and output.

6. SPM Oil Coolers can be flexible and customised to fit the unique needs of various machines and applications. They may be tailored for optimum performance and compatibility with a range of industrial setups in terms of size, cooling capacity, mounting options, and control methods.

In conclusion, SPM Oil Coolers offer qualities like effective cooling, temperature control, compact design, and sturdy construction to manage the temperature of lubricating oil. Benefits include improved system reliability, longer equipment lifespan, increased energy economy, oil quality preservation, and customization options.

Other Detail:

Surface Type : Coated

Material: Metal

Application: Hydraulic and Industrial

Color :BrownProduct details

| Material | Metal |

| Surface Type | Coated |

| Country of Origin | Made in India |

| Pressure | 1000 PSI |

| Cooling Type | Water Cooled |

| Cooler Material | Copper |

| Brand | SCH |

| Usage/Application | Oil Cooling |

| Applications | Hydraulic |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+